In the ever-evolving landscape of waste management and environmental sustainability, the Plastic Pyrolysis Process emerges as a beacon of innovation, offering a transformative solution to the global plastic predicament. Let’s embark on a journey through the intricate nuances of this sustainable alchemy, where discarded plastics find a new life through the magic of pyrolysis.

The Essence of Plastic Pyrolysis

At its core, the Plastic Pyrolysis Process of a plastic pyrolysis machine is a sophisticated chemical metamorphosis, breathing new life into used plastics. Pyrolysis, a term derived from the Greek words “pyro” (meaning fire) and “lysis” (meaning separation), involves the decomposition of complex polymers at elevated temperatures in the absence of oxygen. This controlled degradation yields valuable products and, crucially, mitigates the environmental impact of plastic waste.

The Alchemical Dance of Molecular Transformation

Within the confines of the pyrolysis chamber, a choreographed dance of molecules unfolds. Plastics, once considered a burden on the environment, undergo a meticulous process of thermal degradation. This controlled heat-induced metamorphosis breaks down the long chains of polymers, unraveling them into simpler hydrocarbons.

As the temperature ascends, the molecular ballet intensifies, leading to the liberation of gases and the formation of a liquid known as pyrolysis oil. This liquid treasure, rich in hydrocarbons, holds the potential to be refined into an array of valuable products.

Key Components in the Spotlight

-

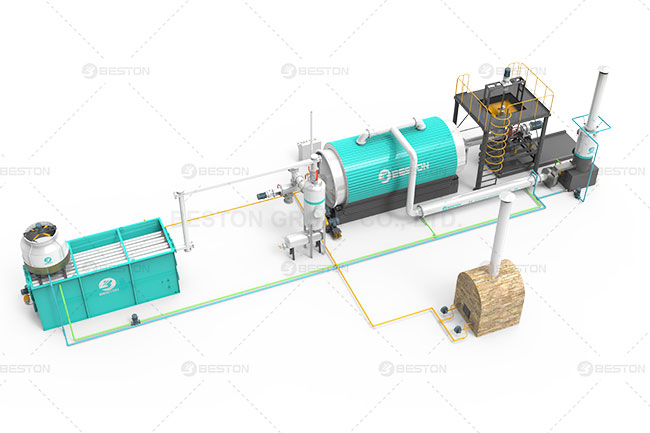

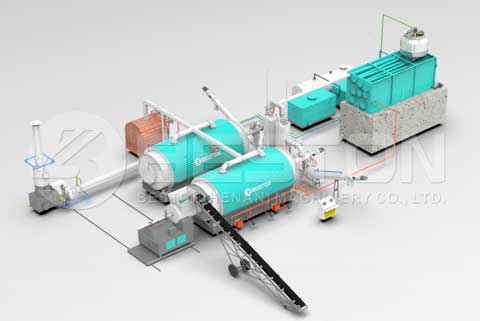

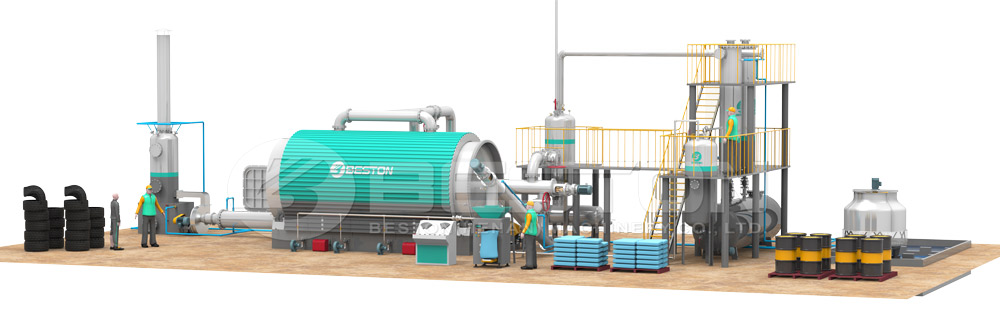

Pyrolysis Reactor

Central to the Plastic Pyrolysis Process is the pyrolysis reactor, a crucible of controlled chaos where the magic unfolds. This reactor of plastic to oil machine provides the ideal environment for the intricate molecular ballet, ensuring the transformation occurs with precision.

-

Condensation System

The condensation system plays the role of an alchemical condenser, capturing the ethereal gases released during pyrolysis. This system ensures that no valuable by-products escape, allowing for their subsequent utilization in diverse applications.

-

Gas Scrubbing Unit

The gas scrubbing unit, a guardian of purity in the alchemical journey, removes impurities from the liberated gases. This step ensures that the end products maintain the highest standards of quality and environmental integrity.

-

Pyrolysis Oil Refinery

The pyrolysis oil refinery stands as the crowning jewel, where the liquid treasure extracted from plastics undergoes further refinement. This process yields a spectrum of valuable products, from fuels to specialty chemicals, opening new avenues for sustainable consumption.

Keywords in the Spotlight

In navigating the labyrinth of plastic pyrolysis, several keywords punctuate the discourse, adding depth to our exploration:

- Circular Economy: The Plastic Pyrolysis Process embodies the principles of a circular economy, where waste becomes a resource, creating a sustainable loop of consumption and regeneration.

- Feedstock: Used plastics, once dismissed as waste, transform into the valuable feedstock for the pyrolysis process, breathing new life into materials that would otherwise languish in landfills.

- Hydrocarbon Recovery: Through the alchemical artistry of pyrolysis, hydrocarbons are recovered from plastics, offering a sustainable alternative to conventional fossil fuel extraction. See the plastic to fuel machine here.

- Upcycling: The process of upcycling takes center stage as plastics shed their single-use stigma, ascending to a higher purpose in the creation of valuable products.

Unraveling the Applications

The versatility of the Plastic Pyrolysis Process extends far beyond the realms of waste management. Its applications resonate across diverse industries, shaping a sustainable future.

Energy Generation

Pyrolysis-derived fuels serve as a renewable energy source, mitigating our dependence on conventional fossil fuels. The liberated gases and pyrolysis oil find applications in power generation, contributing to a cleaner and more sustainable energy landscape.

Specialty Chemicals Production

The refined pyrolysis oil becomes a raw material for the production of specialty chemicals. This not only diversifies the chemical industry but also reduces the reliance on traditional, often environmentally taxing, chemical feedstocks.

Sustainable Manufacturing

By integrating pyrolysis-derived materials into manufacturing processes, industries can champion sustainability. The alchemical transformation of plastics into valuable feedstocks aligns with the ethos of sustainable and eco-friendly production.

A Glimpse into the Future

As the Plastic Pyrolysis Process continues to evolve, innovations in catalyst technology, process optimization, and integration with other waste-to-energy solutions promise an even brighter future. The alchemical journey of plastics, once destined for the landfill, unfolds as a narrative of sustainability, resilience, and environmental stewardship. More information on Beston Group.

In conclusion, the Plastic Pyrolysis Process stands as a testament to human ingenuity in the face of environmental challenges. Through controlled heat and molecular wizardry, plastics undergo a profound metamorphosis, emerging as valuable resources in the tapestry of a circular economy. The alchemical dance within the pyrolysis chamber resonates with the promise of a more sustainable and harmonius coexistence with the materials that shape our world.