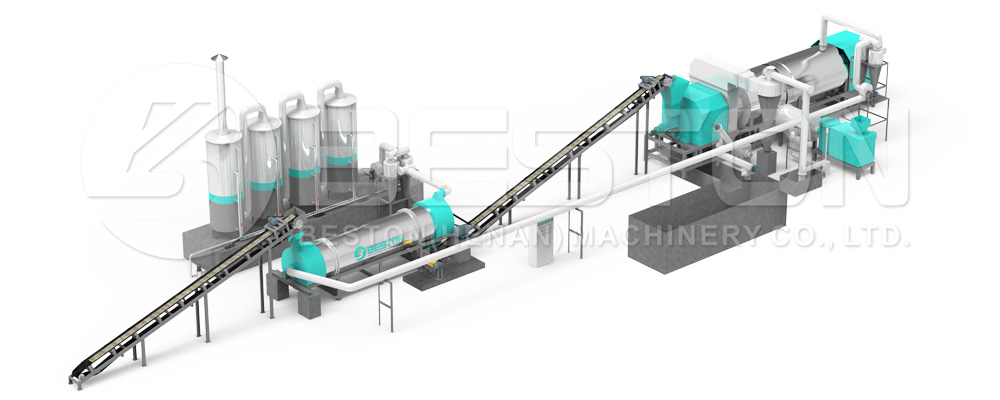

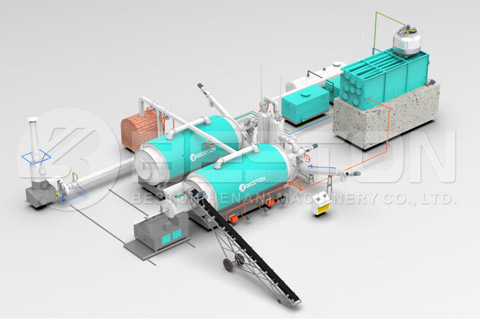

The tire recycling plant project is a big investment, but the cost is going to vary depending on how big the plant is and whether it is automatic or semi-automatic. This plant takes waste tires and turns them into oil. The plant is just the thing you need when you want to produce tons of oil. This plant allows you to do lots of new things and it can help you in a variety of ways. When you are looking for a plant that can help you get a lot done think about using this durable plant since it is so effective. Find a waste tyre recycling plant project report online.

The best way to choose this plant is to do a lot of research so you can decide how you are going to handle installing the plant. You also have to think about how big you want the plant to be. The plant comes in many sizes so you need to have an idea about how much oil you need to produce. When you choose one of these plants it will be easy to find what you need. This machine is simple to get running it can help you in many ways.

The plants produce high-quality oil that is used for heating and running machinery. The oil is very affordable and it can even be processed using a different machine to be turned into gasoline. This plant is very easy to set up and use and it has built-in safety features that keep it safe to use. You won’t have to deal with a ton of problems when you use this machine and it is very easy to get started with it. Click https://bestonturkey.com/waste-tyre-recycling-plant/.

The best thing to do is to rely on the manufacturer to help you get things done. The manufacturer is going to help you choose the right machine for your needs. They also make sure that the machine has all of the features you need. They even ensure that you know how to use it. They also have a powerful follow-up plan that ensures you get all of the after-sales help that you need.

It is important to have support from the manufacturer because they make the experience trouble-free and easy. Working with the manufacturer ensures that you don’t have problems and they make the process affordable and easy to understand. When you are buying a large machine like the tire recycling plant project it is very important that you have all of the support you can get.