In an era where sustainability drives industrial innovation, apple tray making machine manufacturers have emerged as key players in transforming production processes. By combining cutting-edge technology with eco-conscious practices, these manufacturers are redefining how protective packaging is produced for the agricultural sector. The resulting advancements not only minimize environmental impact but also enhance operational efficiency for businesses.

Advancements in Eco-Friendly Material Processing

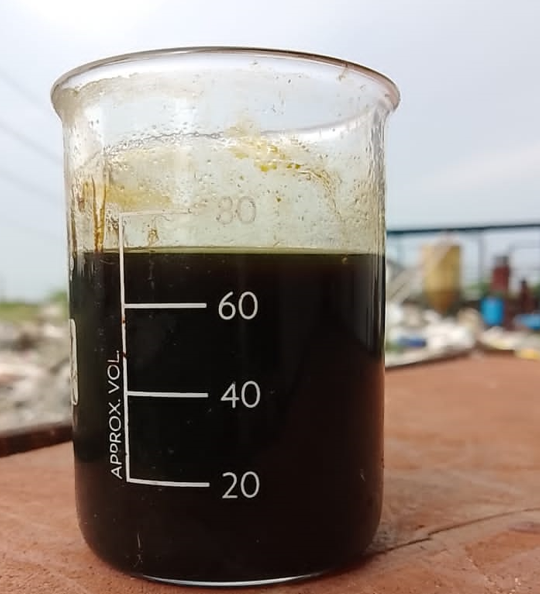

One of the primary ways apple tray making machine manufacturers are revolutionizing sustainable production is through innovations in material processing. These machines are specifically designed to handle recycled paper pulp, a renewable resource that reduces dependency on non-biodegradable materials like plastic.

The molding technology in modern machines ensures high precision, allowing for uniformity and strength in the trays while using minimal raw material. Such precision reduces waste and optimizes the use of resources, making the production process both cost-effective and environmentally friendly.

Integration of Energy-Efficient Systems

Integration of Energy-Efficient Systems

Energy efficiency is a cornerstone of sustainable production. Tray making machine is increasingly equipped with advanced energy-saving features such as automated temperature controls, efficient drying systems, and power-regulating mechanisms.

For instance, modern drying systems use hot air recirculation or heat recovery techniques, significantly lowering energy consumption without compromising production speed. These innovations not only reduce carbon emissions but also align with global sustainability goals, making these machines attractive to eco-conscious producers.

Automation for Enhanced Productivity

Automation is playing a critical role in elevating the efficiency of pulp moulding machinery. Automated feeding, forming, and drying systems ensure seamless operations, reducing the need for manual intervention. This results in higher production rates and consistent product quality, even for large-scale operations.

Moreover, many manufacturers are integrating smart technologies such as programmable logic controllers (PLCs) and sensors into their machines. These systems allow for real-time monitoring of production parameters, ensuring optimal performance while minimizing energy and material waste.

Modular Designs for Versatility

To meet the diverse needs of the agricultural sector, manufacturers are adopting modular designs for their machines. These designs enable businesses to produce a range of tray sizes and shapes, accommodating varying quantities of apples and other produce. Such versatility supports the broader goal of waste reduction, as the machines can be adapted to different production requirements without necessitating new equipment.

Promoting a Circular Economy

Similarly, egg tray production machine is central to the adoption of circular economy principles in the packaging industry. By utilizing waste paper and other recycled materials as inputs, these machines create a closed-loop system where resources are continuously reused. This not only diverts waste from landfills but also reduces the environmental footprint of packaging production.

Manufacturers are also investing in research to improve the quality of trays produced from recycled inputs. These efforts ensure that recycled materials meet the durability and protection standards required for agricultural packaging.

Supporting Local and Global Sustainability Goals

The innovations driven by apple tray making machine manufacturers have a direct impact on both local and global sustainability initiatives. By enabling businesses to transition to biodegradable packaging solutions, these machines contribute to the reduction of plastic waste—a significant environmental challenge.

Furthermore, the adoption of these machines supports farmers and distributors in meeting the growing consumer demand for eco-friendly packaging. This alignment with market trends ensures that sustainable practices are economically viable, fostering long-term adoption.

Conclusion

Apple tray making machine manufacturers are playing a transformative role in advancing sustainable production. Through innovations in material processing, energy efficiency, automation, and modular design, these machines are setting new standards for eco-friendly packaging. By facilitating the use of renewable resources and supporting a circular economy, they not only address environmental challenges but also offer businesses a pathway to greater efficiency and profitability. As sustainability continues to shape industrial practices, these manufacturers remain at the forefront of change, driving progress toward a greener future.