If you run a company that deals with tyres or biomass in any way, you may want to consider investing in a recycling plant. There are numerous benefits to getting an ideal biomass recycling plan. If you wish to leverage these benefits, then you need to find not only the best machinery in the market but one that meets your needs. In this read, we are going to cover the tips for finding an excellent biomass pyrolysis plant.

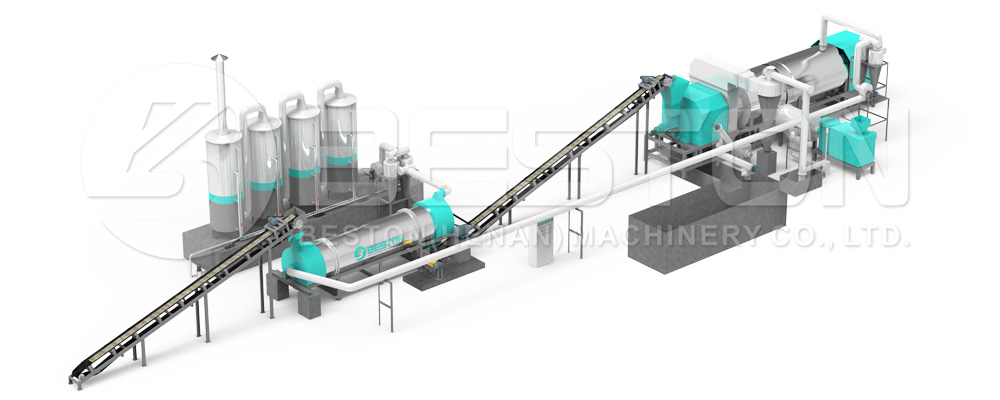

The first thing is to look at the various plants available and compare them as not all are created equal. The more you compare and the more manufacturers or dealers you check out, the more chances you will get for the equipment you need. Apart from that, quality is essential, so ensure you find machinery that’s built to last.

The features you need is another important thing to consider. Do you want a biomass pyrolysis plant that works fast, or has a lot of power, with modern safety features, or are you just looking for machinery with basic features? Once you are in terms with this, you will have an easier time in the decision-making process and will focus on things that actually matter. Click here to know more about wood charcoal making machine.

The price of the machinery is another vital factor, as it’s the primary aspect of the cost. Ensure you get a plant that provides value for the price. It is also a food idea to go as many reviews as you can from verified customers about the machinery. This combined with testimonials can give you a pretty good idea of what to expect from your investment as well as the manufacturer’s service.

If you are in the recycling business or a niche like automotive manufacturing, you should invest in a recycling plant. Junkyards can ideally benefit from owning a tyre recycling plant.

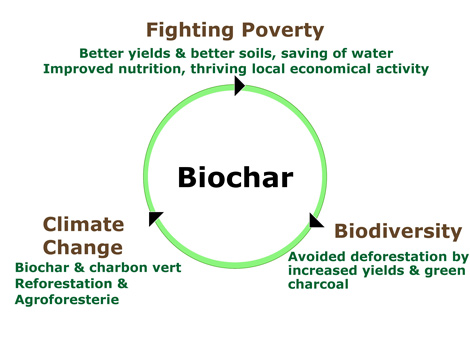

Advantages of a Biomass Recycling Plant

There are numerous advantages to owning a charcoal making machine, the primary one being able to get rid of waste in a profitable and efficient manner. All you need to do is put the waste in the plant and follow the instructions. How quickly the machinery can handle this depends on its capacity and power rate as well as whether it is semi or automatic.

Another advantage is that you can reuse the tyres after being broken down. Once the biomass has been recycled, you can decide how to use it. In fact, more and more companies today are using recycled products to create new ones, which saves them a lot on raw materials purchase and transportation.

Lastly, you get to save a lot of money by investing in a coconut shell charcoal machine. That’s primarily because you will not have to haul your tyres to site as you already have yours. Disposing of these materials can be costly as you have to hire a company for proper disposal. If you have a lot of biomass to dispose of, it is best to invest in a plant. It might cost a lot, but if you do your homework and get the right one, it will save you a lot in the long run.