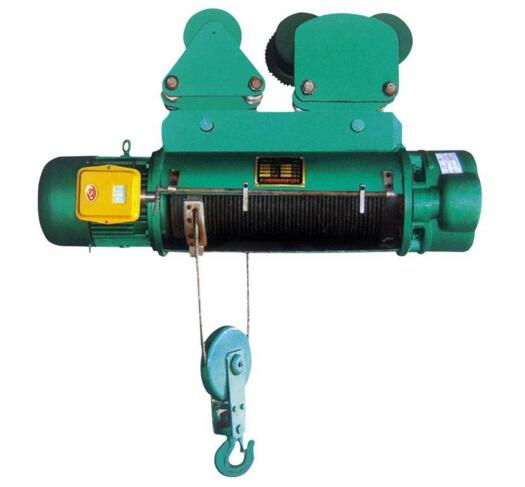

Electric hoists can be one of the most useful things for any type of business, and it is an important equipment for the overhead cranes. But although they add a lot of benefits in terms of saving on labor as well as on time, they do have to be maintained. Unlike manual hoists, electric hoists need more frequent maintenance. A poorly maintained electric hoist can cause problems in a number of different ways. They can start to rust up or gum up and become slow to move on their tracks as a result, as well as slow to retract and extend the hoist. This can slow down your business operations dramatically. A badly maintained hoist that is left to rust and decay for too long can even fail or stop working entirely, which can mean a delay in your business operations that can cost quite a lot in time and money to get fixed. A hoist that has become dilapidated and poorly functioning can also fail catastrophically, such as if a rusted hoist chain breaks and drops a load. This can lead to loss and breakage of the goods that are being transported, as well as to injuries and bodily harm to employees and staff who may be nearby as a result of falling heavy objects and debris flying into the air as a result.

So, in order to prevent these consequences from happening and costing you both time and money at your business, there are some simple things you can do to maintain your electric hoist and keep it in good and speedy working condition. According to different uses and different cranes, the workplaces for hoist are also different. If your electric hoist is being kept outdoors mainly for double girder overhead cranes, then it may be highly susceptible to rust and environmental damage. One easy way to protect your electric hoist from damage from rain and snow and other weather such as dust storms is to cover it in a plastic tarp when it is not being used. You can buy plastic tarps with holes on the corners for tying together for very cheaply on many internet sites. Another option, which is more useful if you will need to be operating your electric hoist while bad weather conditions are ongoing, is to purchase a protective plastic casing for your hoist. These are very inexpensive, and fit snugly around the hoist to protect it from weather damage while at the same time allowing it to operate freely. When an electric hoist is used for single girder overhead cranes, the lifting capacity may be smaller as 2 ton o 3 ton (Grua Viajera 3 Toneladas). It is much easier for maintenance.

Other things that you should do to keep your electric hoist in good working order include regularly checking on its lubrication (lubricación) to make sure that it is in good shape and regularly cleaning off the hoist tracks. The hoist tracks are a source for debris and dirt that can get into the mechanisms of your electric hoist (mecanismos de sus electricos polipastos), and not many people are aware of this. Cleaning off the hoist tracks at the end of every day is one of the easiest ways to extend the lifespan of your hoist dramatically, as it will be able to run smoothly since it will be free from dust and dirt in its mechanisms and gears.