In this article, we will discuss the Disadvantages of a Waste Tyre Pyrolysis Plant, as well as the Benefits, Costs, and Installation of this type of plant. The next section will discuss the installation process. This article is not an in-depth review of Waste Tyre Pyrolysis Plants, but a quick review of the features and benefits of tyre pyrolysis plant.

Disadvantages

A waste tyre pyrolysis facility turns non-degradable materials into valuable products, such as oil. This process requires routine maintenance to achieve optimum production efficiency and lower operational costs. The benefits of this process include reduced production costs and a higher return on investment. However, there are several disadvantages to waste tyre pyrolysis. Let’s look at some of them.

Initially, a waste tyre pyrolysis process produces an oil that has high aliphatic hydrocarbon content and low aromatic hydrocarbon content. This results in higher C/H atomic ratios, which are similar to those of crude oil. However, this type of oil contains high levels of limonene, which may affect the economic feasibility of the process.

Benefits

A waste tyre pyrolysis facility can provide a renewable source of energy. The by-products of pyrolysis plant include carbon black, steel wire, and improved carbon. The carbon black is a good substitute for diesel fuel and has many industrial uses. The steel produced by a waste tyre pyrolysis plant can be used to produce steel.

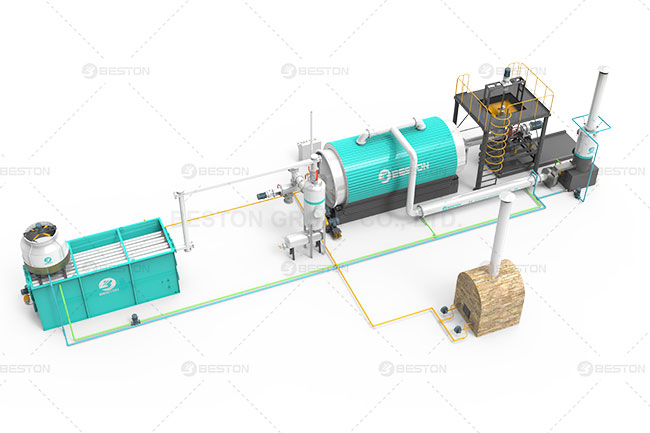

A continuous tyre pyrolysis plant is a highly efficient way of converting waste tyres into oil. It can reduce emissions from combustible gases and can help improve the environment and economic benefits. The new-type waste tyre pyrolysis plant is compact and scientific, and its design follows international standards. Its operating efficiency is high and its handling ability is strong. The waste tyre pyrolysis plant can reduce labor costs and increase production efficiency. It can also reduce energy costs.

Costs

Setting up a waste tyre pyrolysis unit is relatively simple. There is no construction cost, except for a roof. The costs involved in operating the plant are minimal, and consist of operating expenses such as power consumption and labor salaries. The waste oil produced from pyrolysis is used for industrial and commercial purposes and contains approximately 40 to 45 percent recycled scrap tyres. Fortunately, these oil products are very inexpensive to acquire and transport. See the tyre pyrolysis plant cost here.

A pyrolysis plant’s overall cost is directly related to its efficiency. The higher the efficiency, the more expensive the equipment. Propane is the preferred fuel for waste tyre recycling. Propane gas is relatively inexpensive, but its calorific value is slightly higher than natural gas. Propane gas also has greater energy potential. Propane gas can be used to fuel a ten ton-per-day waste tyre recycling facility.

Installation

The basic steps of installing a waste tyre pyrolysis facility are collection of the materials, collecting the waste tires, and paying the costs. The process costs vary greatly depending on location, but in many countries, such as Mexico and China, this equipment is available for very cheap or for free. Then, the materials are disposed of properly. A waste tyre to oil plant is the most efficient way to reduce the amount of waste you produce.

To install a waste tyre pyrolysis machine, it is important to complete the following parts: the slide valve, the plug valve, the external heater, and the lifting pipe. The safety facilities should be complete as well, such as a gas outlet and a spring hanger. In addition, the bolts and fittings of the equipment should be tight and neat. The gas outlet should be properly closed and the graphite ring must be replaced every two months. The maximum pressure inside the furnace cannot exceed 1300 degrees.