Do you want to buy biochar production equipment? Take your time. As a first time buyer, you may not know the best sellers in this industry. Some sellers are untrustworthy. They have expensive prices. And they have poor customer service. Do not use them because you will never use their equipment for a long time.

The following are the factors to consider before choosing a biochar production equipment.

1. The Quality

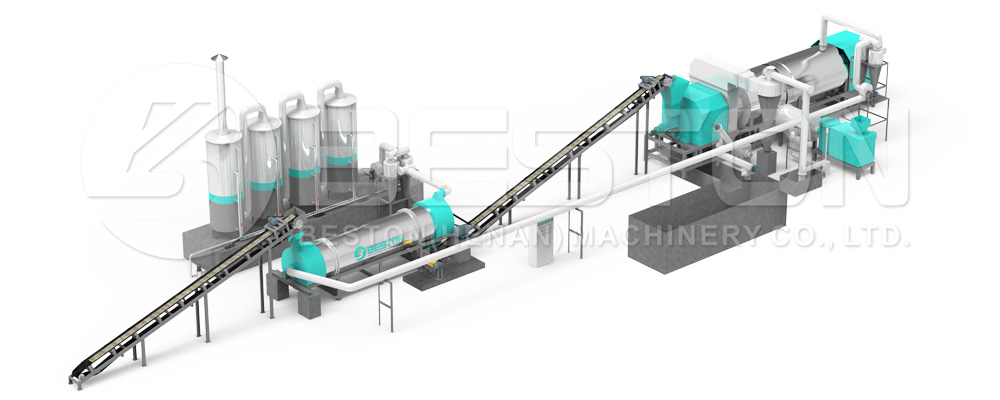

The quality of the equipment is important. Low-quality equipment has a short life span. It is expensive to maintain. You may end up spending more money maintaining that equipment.

How do you know the quality of this equipment? Check the reputation of the manufacturer. Reputable manufacturers make high-quality equipment. Click here to know more: https://bestonpyrolysisplant.com/.

Also, you may have to spend more money on high-quality equipment. Do not worry about the initial cost of this equipment. You will make more money using that equipment. In fact, it is much cheaper to maintain. Therefore, you will save a lot of money on maintenance costs.

However, once you know the quality of the equipment you want to buy, look a seller that sells that equipment. Make sure the seller is selling genuine equipment. Because some sellers sell fake equipment that looks like the original equipment. Do not fall for them.

Consider the seller. This is because some sellers are unreliable. They have poor customer service. Do you know why? Because they do not care about their customers. To avoid losing your money to the wrong sellers, you need to look for reputable sellers.

Reputable sellers are the best. This is because they have a good history. They sell original biochar production equipment. They provide after-sale services. Therefore, when you have a problem with your equipment, you just call that seller. The seller will send a professional to fix your equipment. Get competitive palm kernel shell charcoal machine price here.

However, there are inexperienced sellers. Do not choose them. You do not know how long they will be in this business. They can go out of business anytime. If they had given you a warranty, forget about the warranty. Businesses, which are out of business, do not honor their warranty.

3. The Manufacturer

Why use a manufacturer? Some manufacturers are the best. They have affordable prices. They can charge cheap prices because they do not have a problem selling their equipment. In fact, they work with several suppliers and other companies. And they sell their equipment directly to their customers. Why not visit the website: https://bestonpyrolysisplant.com/charcoal-making-machine/.

How do you choose the right manufacturer? You must know the reputation of the manufacturer. A good manufacturer has a good reputation. It has been making biochar production equipment for a long time. Most people love their equipment. That is why they have a lot of good reviews.

Do not use new manufacturers. They are still learning how to make this equipment. In fact, they cannot afford the best raw materials for making this equipment. If you buy their equipment, you may never use that equipment for a long time. It is expensive to use in the long run.

These are the factors to consider when looking for biochar production equipment.

More information on blog: http://arriedman.webstarts.com.