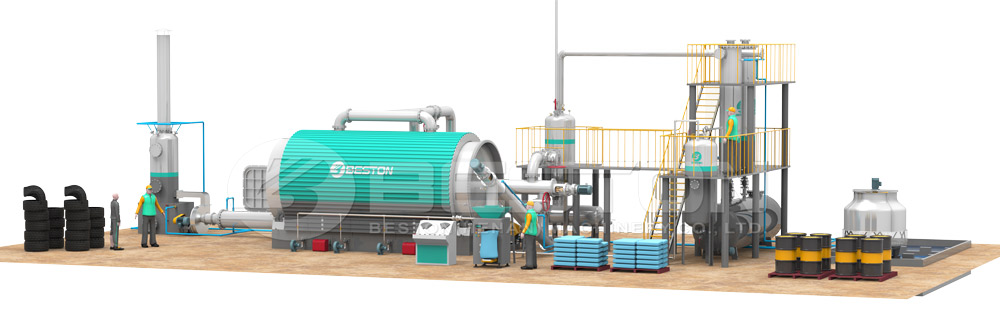

Are you interested in finding a tyre to oil Plant Price that will be affordable for your business? It is a very important type of machine that can take rubber tyres, and easily convert them into burnable liquid fuel. During the pyrolysis process, these materials are broken down, converted into both liquid and solid fuels. If you are only interested in producing and selling the oil that is made through this process, you can easily produce a substantial amount using these unique plants. This is how you can quickly find a tyre to oil plant price that will be affordable for you.

Why This Will Be A Good Investment For Your Company

Most businesses will agree if they can recycle certain materials, it can help their company save money. If you are in an industry where you are producing tyres, or if you are recycling them through your municipal solid waste plant, you should have a way of converting these into something useful. In most cases, or at least over the last few decades, landfills have become full of rubber tyres that have been discarded. As billions of them are added into the ground every year, this is a wonderful way to prevent this from constantly occurring. Click here to know more: https://bestonpyrolysisplant.com/.

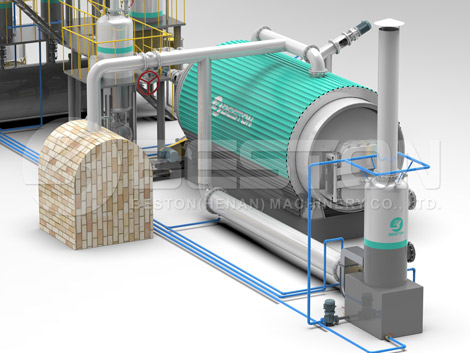

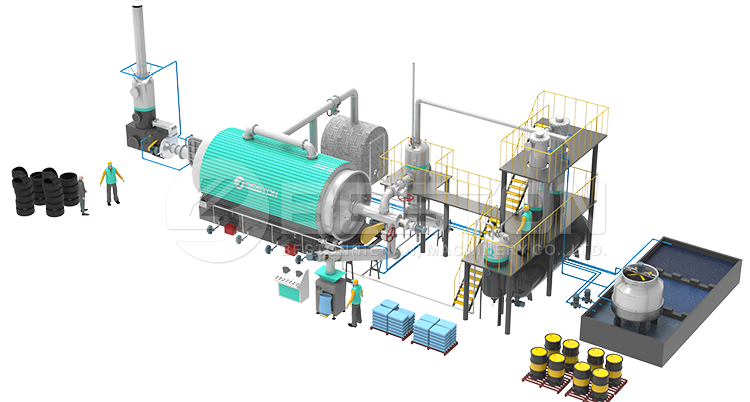

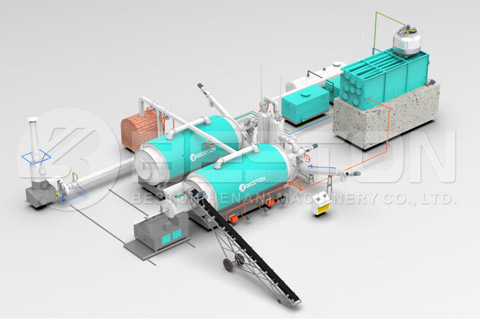

The conversion process happens when these materials are chipped up into small pieces, put into the reactor, and subsequently converted into the oil. High heat is used, maintained at a constant pressure and temperature, until the chemical processes over. When it is done, you will not only have burnable fuel in the form of liquid to use and sell, but you will have charcoal as residue as well. This is a fantastic way to increase the revenue that your business generates, all the while getting rid of rubber tyres that are very hard to discard of today.

Where Should You Begin Looking For These Time To Oil Plants?

Searching for these products is a simple process. It shouldn’t take you longer than a few hours to locate several good deals. The cost will likely be several hundred thousand dollars, but you can often find good deals on both new and older models. It depends on how large the company is, and how much they are willing to discount their prices. If you are looking for one now, a quick search for a scrap tyre pyrolysis plant will lead you to several that are very affordable.

Once you have secured one, you can set it up quickly, and start to produce as much oil as you want from the rubber tyres that you have at your disposal. Once you have discovered a good source for these tyre to oil plants, you can then begin to assess them based upon their capabilities. In no time, you will have one delivered that will offer you the ability to create as much oil as you want. Find out more today by researching tyre to oil plant prices that will be affordable for you. More information on the blog: https://www.reddit.com/user/bestongroup/ here.