With the world’s population steadily increasing and urbanization on the rise, the management of organic waste in cities has become a paramount concern. As urban areas grapple with the challenges of waste disposal, carbonization equipment emerges as a promising solution.

The Urban Organic Waste Challenge

Urban centers generate an immense amount of organic waste daily, consisting of food scraps, yard trimmings, and other biodegradable materials. Traditional waste management methods such as landfilling and incineration are not only environmentally harmful but also increasingly impractical due to limited space and stricter environmental regulations.

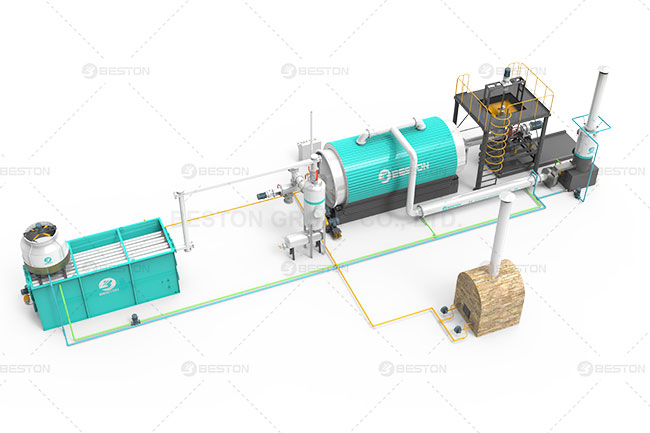

Carbonization Equipment: A Sustainable Solution

Carbonization, often referred to as pyrolysis, is a thermal decomposition process that converts organic materials into biochar, a stable form of carbon, and other valuable byproducts. Carbonization equipment facilitates this process and offers numerous advantages for urban organic waste management.

- Reduction in Volume

Sewage sludge carbonization machine significantly reduces the volume of organic waste. Through the process of pyrolysis, the equipment can decrease the original waste volume by up to 90%. This reduction is particularly crucial in densely populated urban areas with limited landfill space.

- Production of Biochar

The primary product of carbonization is biochar, a highly porous and stable carbon-rich material. Biochar has multiple applications, including soil improvement, carbon sequestration, and wastewater treatment. Incorporating biochar into urban agriculture can enhance soil fertility and reduce the need for chemical fertilizers.

- Energy Generation

Carbonization equipment can produce valuable energy products, such as syngas and bio-oil, during the pyrolysis process. These products can be harnessed to generate heat and electricity, providing a sustainable energy source for urban areas. This aligns with the growing trend of decentralizing energy production in cities.

- Circular Economy

The adoption of biochar production equipment promotes the concept of a circular economy. Organic waste, once considered a problem, becomes a valuable resource. Biochar and other byproducts can be integrated back into various urban systems, creating a sustainable and closed-loop waste management cycle.

- Emission Reduction

Unlike traditional waste incineration, carbonization is a low-temperature process that minimizes harmful emissions. The controlled conditions of carbonization equipment ensure that harmful pollutants like dioxins and furans are not released into the atmosphere. This significantly improves air quality in urban environments.

Case Studies

Several cities worldwide have recognized the potential of carbonization equipment in organic waste management and have implemented successful initiatives:

- Tokyo, Japan

Tokyo has embraced carbonization technology to manage its organic waste efficiently. The city employs rice husk charcoal making machine to process food waste from households. The resulting biochar is used in urban agriculture projects, contributing to the city’s food security and reducing the environmental impact of waste disposal.

- Stockholm, Sweden

Sweden’s capital, Stockholm, has adopted large-scale carbonization equipment to manage its organic waste. The city’s waste-to-energy plants use pyrolysis to convert organic materials into bio-oil, which is then utilized for district heating. This sustainable approach significantly reduces the city’s reliance on fossil fuels.

- Singapore

Singapore, known for its innovative urban planning, has initiated a pilot project that incorporates carbonization equipment into its waste management system. The project aims to convert organic waste into biochar, which will be used to enhance soil quality in urban parks and green spaces.

More information about charcoal machine is in Beston Group.