Wood carbonization is a process that uses heat and steam to turn wood into charcoal. This has been used for centuries as an alternative fuel source, but it also has many other applications. Wood carbonization can be used in different industries such as steel production, paper manufacturing, and food processing plants.

How Does it Work?

Wood carbonization (maquina para hacer carbon vegetal)is a process that utilizes heat and steam. The amount of time it takes for wood to carbonize varies, but on average, it takes about two to three hours of exposure to the high-temperature and humid environment.

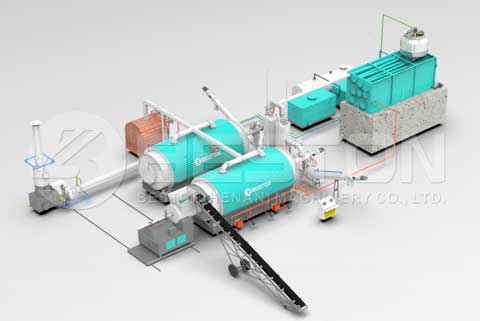

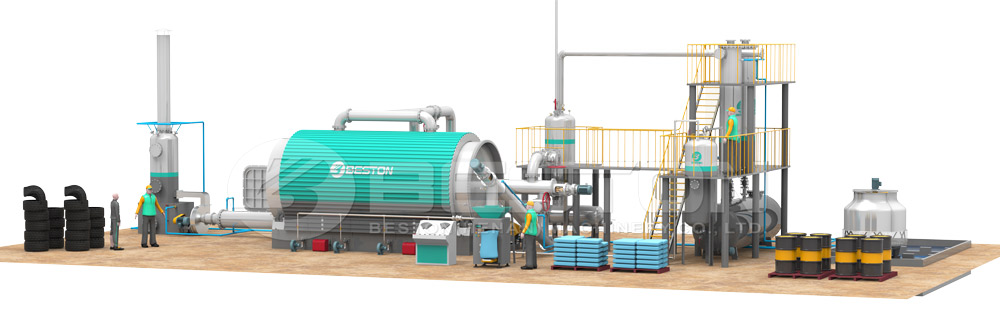

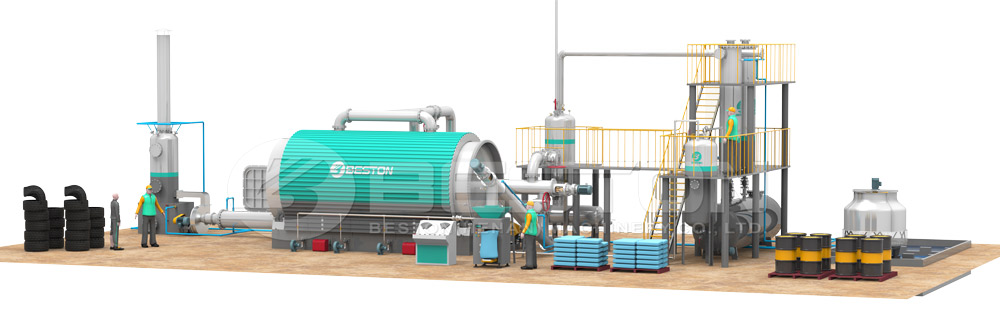

A kiln is needed for this process and can be powered by natural gas or solid fuels such as coal. When the pressure inside the kiln reaches a certain level, it becomes hot enough for the wood to break down into charcoal(https://www.bestoneco.com/maquina-de-carbonizacion-montado-sobre-patines/). This process creates more heat, which will cause more reactions.

The charcoal created during the wood carbonization process is one of the most common fuels in developing countries because it does not require any refining.

Why Does it Matter?

Wood carbonization is vital because business owners can use it in various industries, which makes its applications limitless. It has also become important in the past few years because it is one of the most sustainable ways to produce energy.

Companies that use this process do not need to rely on fossil fuels, and they can reduce the amount of carbon dioxide emissions in their plants. The trees used for wood carbonization are also renewable, making them more environmentally friendly than coal or natural gas.

It’s important to remember that this process isn’t just about energy production. It also has many other uses that are important to various industries.

Applications of Wood Carbonization

Many industries take advantage of wood carbonization(hornos metalicos para hacer carbon) because of its various applications. These include:

Steel Production Plants – Steel production plants often use wood as an additive for blast furnaces. The charcoal gives off heat, which allows the furnace to be more efficient and produce steel faster.

Water Filtration – Activated charcoal is commonly used in water filtration systems because it can remove contaminants easily without losing its effectiveness over time. This makes activated charcoal one of the best options for water filtration.

Paper Manufacturing – Some paper manufacturers use wood as their main source of material because it gives them higher quality and consistency than other materials do.

Food Processing Plants – Food processing plants utilize activated charcoal to filter out impurities in sugar and honey, making the end product purer. It can even be used in soft drinks to make them look more appealing.

Drawbacks and Limitations

Although wood carbonization (Beston (Henan) Machinery co.Ltd)has many applications, it does have its drawbacks and limitations. For example, the process requires a very large amount of energy to function properly, making it costly for some companies.

Another drawback is that this process does not remove all of the contaminants from different materials. Activated charcoal effectively removes certain types of impurities, but it may miss others that can still be harmful to humans and animals in large quantities. However, this process has become more popular because researchers are able to work on improving its limitations by experimenting with different recipes and procedures for wood carbonization.