There are several ways to look at the cost of establishing a pyrolysis plant. If you are new to business, you might consider only the cost of buying a new plant. However, experienced investors or business owners in this space understand the importance of considering a variety of cost heads to arrive at the overall cost of owning and operating a pyrolysis plant. In this article, we will discuss the true cost of establishing and operating a pyrolysis plant and help you arrive at the true pyrolysis plant cost in order to make an informed decision.

Cost of Machine

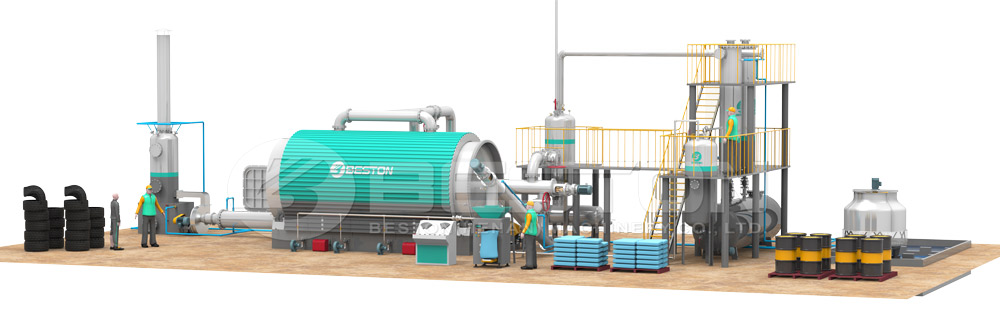

It is a rather straightforward process. The pyrolysis plant cost depends on the capacity, underlying technology, level of automation, quality of materials used for making the plant and certain other factors. It is something that should be readily available if you are willing to do the work. In order to figure out the cost of pyrolysis plant, you should first find out manufacturers who are well known in the industry for quality of their products. Once you’re satisfied with the quality of products made by certain manufacturers, you can discuss terms with their sales team in order to get an idea of the final cost of the plant. Do not forget to take into account the shipping cost object as well as cost of customs and other things. The manufacturers usually have a good idea of the overall cost and they should be able to give you a rough estimate of what the plant is going to cost when it finally arrives at the installation site.

Cost of Maintenance and Repairs

Pyrolysis process takes place under high temperature and pressure which means there is going to be constant wear-and-tear on the machinery. Also, the end products derived from pyrolysis process tend to be abrasive in nature which will also affects the life of various components. This is why, you need to figure out the expected cost of maintenance and repairs. Do not take the manufacturer’s word for it. Instead, you should talk to people who already have that plant as they will be able to give you a better idea of the expected maintenance and repair costs in the regular course of operations. Find a machine from reliable pyrolysis machine manufacturers here.

Operating a pyrolysis plant also costs money. After all, you have to pay salaries to the workers, pay for fuel, pay for water, land and a lot of other things. In short, one of the primary expenses of in this business is the cost of utilities as it takes a lot of energy. This is why, you need something that is energy efficient and keeps your utility costs in check. You should also consider a continuous waste tyre pyrolysis plant as it will save you a lot of money on salaries, in the long run.

Conclusion

Overall, pyrolysis plants have turned out to be a successful business for most entrepreneurs. However, some business owners have an edge over their competitors as they were smart about choosing the right machine and right technology that paid them dividends in the long run. This is why, you can’t establish a pyrolysis business and expect it to run profitably without doing proper research. So, keep the above-mentioned tips in mind in order to arrive at the true pyrolysis plant cost and to make an informed decision about choosing the right one. More information on pyrolysis oil plant.