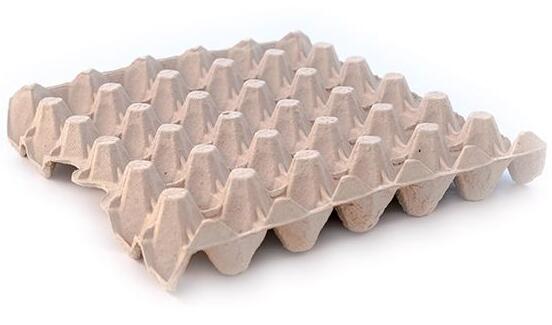

The common chicken egg is an orb of wonder. Its unique contents have a high nutritional value and special composition that makes eggs a staple of every cuisine and kitchen across the planet. This means that over 3 billion eggs will be transported from chicken coops to kitchens every day. But this transportation of eggs to the kitchen has always been fraught with disaster due to the frail nature of the egg’s shell.

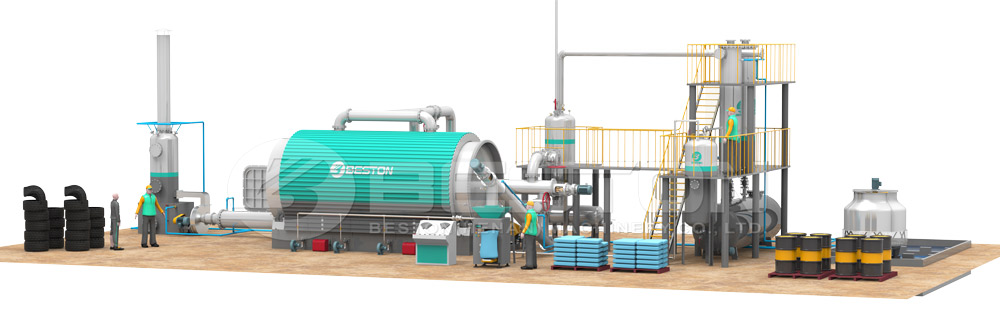

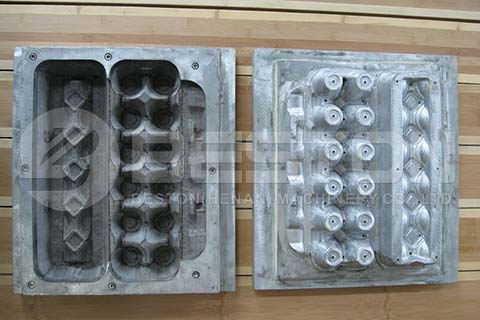

For this reason, many thousands of egg carton trays are needed each day. Today’s leading manufacturers have designed cutting-edge equipment to aid in this important aspect of production. The right egg carton machine for sale will help you avoid loss of profitability due to broken eggs in transportation and keep you supplied with the right amount of egg cartons to support your operations.

If you are looking to get a machine of this type, there are some important considerations to keep in mind.

Quantity of Production

The most important consideration you will have will be the quantity of production that you will need to meet the capacity of eggs you are packing. There are different machines that will support different demands. Each egg carton making machine will be capable of producing a certain number of cartons in an hour. The more powerful varieties will have the capacity to produce as many as 6000 egg carton trays in an hour. While those on the lighter end of the market can produce around 1000 in an hour.

A good egg carton making machine can last for many years, so be sure you have carefully considered your demands both now and in the future when you choose the pulp moulding machinery for your needs.

Budget Parameters

The next important question will be about the resources you have budgeted for this investment. This way you can consider exactly which advantages you would like to emphasize in your egg carton making machine. Different types of machines come with different advantages. These specifics can affect the price of the machine. Therefore, it is a good idea to know what you need so you are not paying for anything superfluous.

Automated or Semi-Automatic

One example of extras that can benefit your operations or be another hassle to deal with is the automated and semi-automated process. The automatic egg tray making machine will fetch a higher price but will cut down on the costs of manual labor. On the other hand, the semi-automated machine will be a smaller investment but will require constant attention to keep running properly. This will mean paying more in the long run. Get more details: https://pulpmouldingmachines.com/egg-tray-making-machine/semi-automatic/.

Bespoke Manufacturing Plants

Finally, you will want to make sure that the egg carton making machine you are considering for your needs matches the raw materials you have to work with. Most egg carton making machines will convert one or more of the following into a valuable product with high demand in the food industry.

Final Notes on The Best Egg Carton Manufacturing Plant for You

Never forget that the right egg tray machine manufacturers will be the one that makes your life easier and saves you time and money. For this reason, it is important to begin your search with a clear idea of the type of machine you need to suit your operations perfectly.