These days, environmental concerns are on the minds and tongues of many people, from governments to companies to private individuals. While many different citizens and groups are doing their part, it seems as if there are far, far too many ways to contribute to mending the damage humanity has done to the planet and preventing further damage that will inevitably make humans sick. Of particular note is humanity’s knack for producing incredible amounts of waste products beyond that of any other species on earth. Our trash is truly a sight to behold, be it an overflowing wastebasket or a landfill as far the eye can see. While a reduction of waste and a reuse of waste products is always preferable, recycling waste products of all kinds is also a good idea for both environmental and economic reasons. However, it can also be environmentally and economically responsible to re purpose waste products. Once such means of re purposing human made garbage is the waste plastic pyrolysis process. In the market, there are many pyrolysis plant manufacturers. Find a good waste pyrolysis plant from them.

Pyrolysis is chemically defined as the decomposition of organic material at highly elevated temperatures without the presence of oxygen or halogen. This induces a change in both the chemical composition and physical phase of the material being put through the process. A pyrolysis process is always irreversible. The plastic to oil machine is used in a great many different human endeavors, from the production of all kinds of charcoal to a dizzying array of cooking techniques. It can also be used to transform biomass into fuels and transform raw hydrocarbons from oil into more usable forms like gasoline. Some investors will choose small mini skid-mounted pyrolysis plant because of portable feature.

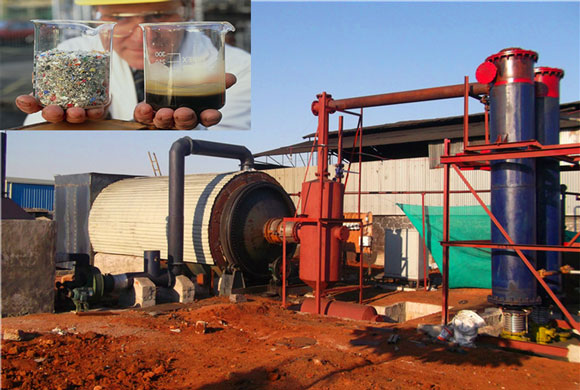

The plastic to fuel oil process itself requires plastics waste. The plastic waste is heated up in a specialized device devoid of all oxygen and halogens. During the process, the plastic waste decays under the weight of the device’s heat but rather than burning as it would in an oxygen-fueled flame environment, it simply breaks down into component molecules.

The resulting substance is a liquid fuel that is chemically remarkably similar to diesel fuel, save that it has a higher cetane value and lower sulfur content than tradition diesel. A higher cetane value means that the engine will run quieter (always preferably with notoriously loud diesel engines) and in some engines will improve efficiency, while a lower sulfur content means that less toxic substances will find their way into the air as the engine runs. Via plastic pyrolysis machine, transforming plastic waste into this kind of fuel is desirable for a number of reasons. The first is that it far more cost effective to recycle fuel from waste plastic than it is to mine for it. The second is that it lessens dependence on foreign oil to fuel a nation’s transportation infrastructure with diesel.

More information about the waste plastic pyrolysis process, you can view this site – Beston Henan.