The pyrolysis plant stands as a testament to the symbiosis between technological innovation and sustainable waste management.

I. Conceptual Framework

A. Pyrolysis Plant Definition and Purpose

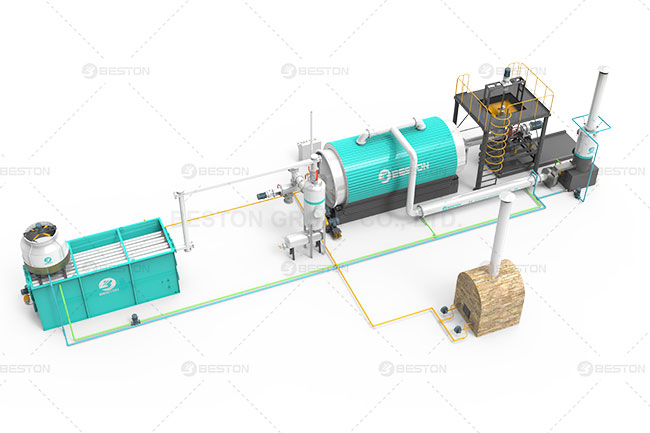

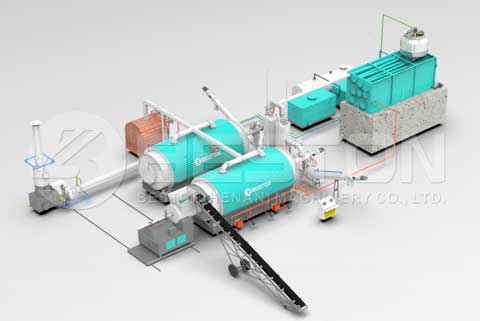

At its essence, a pyrolysis plant is an ingenious apparatus that employs the principle of thermal decomposition to convert organic materials into valuable byproducts. The process is inherently eco-friendly, representing a pivotal shift towards circular economy practices.

B. Pyrolysis Mechanism

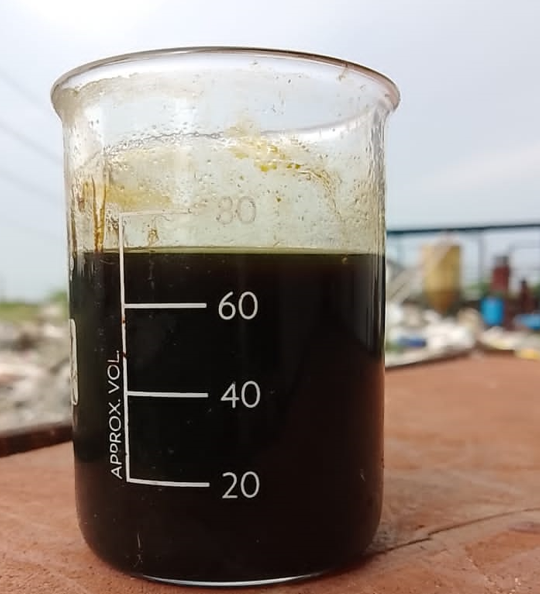

The heart of a pyrolysis plant pulsates with a thermal ballet, orchestrated by controlled heat in an oxygen-deprived environment. This induces the breakdown of complex organic structures, yielding combustible gases, liquid bio-oil, and a residue of char.

II. Design Considerations

A. Reactor Configuration

- Fixed Bed Reactor: The bedrock of many pyrolysis plants, this configuration fosters a gradual and controlled thermal degradation, optimizing the yield of valuable byproducts.

- Fluidized Bed Reactor: A dynamic alternative, leveraging fluidization of the material to enhance heat transfer and reaction kinetics, culminating in a more efficient conversion process.

B. Feedstock Flexibility

The tyre/plastic pyrolysis plant design should accommodate diverse feedstocks, ranging from biomass and agricultural residues to plastics. This versatility enhances the plant’s adaptability to varying waste streams, rendering it an invaluable asset in waste management.

C. Heat Transfer Optimization

In the alchemy of pyrolysis, heat is the catalyst for transformation. Efficient heat transfer mechanisms, such as conduction, convection, and radiation, must harmonize within the plant’s design to ensure optimal energy utilization.

D. Gas and Liquid Collection Systems

The judicious collection of combustible gases and liquid bio-oil is a design nuance that warrants meticulous attention. An intricate network of collection systems ensures the harnessing of these valuable byproducts with minimal losses.

III. Operational Parameters

A. Residence Time Optimization

Within the reactor’s crucible, the material undergoes a temporal metamorphosis. The residence time, the duration material spends in the reactor, must be calibrated for each feedstock to extract maximum value without compromising quality.

B. Catalytic Influence

The incorporation of catalysts in the pyrolysis plant design is a strategic choice. Catalysis can enhance the pyrolysis reaction, expedite the process, and influence the quality of the resulting byproducts.

C. Temperature Control

The oil sludge/plastic/tyre pyrolysis plant‘s performance hinges on precise temperature control. The process demands a delicate equilibrium; temperatures too high may lead to undesired side reactions, while inadequate heat may impede the overall efficiency.

IV. Environmental Considerations

A. Emission Control Systems

While pyrolysis epitomizes a cleaner alternative to conventional waste disposal methods, the pyrolysis plant should incorporate robust emission control systems. This ensures that any residual emissions meet stringent environmental standards.

B. Byproduct Utilization

The char residue, often overlooked, holds latent potential. Creative avenues for its utilization, such as soil amendment or carbon sequestration, amplify the environmental sustainability quotient of the pyrolysis plant.

V. Economic Viability

A. Life Cycle Cost Analysis

Beyond the environmental merits, the economic viability of a pyrolysis plant demands scrutiny. Life cycle cost analysis provides a comprehensive lens, encompassing capital investment, operational costs, and revenue streams from byproduct sales.

B. Market Integration

The oil sludge pyrolysis plant should seamlessly integrate with existing markets for bio-oil, syngas, and char. Navigating these markets requires strategic acumen to position the plant as a valuable contributor to the circular economy.

VI. Future Prospects and Innovations

As technological frontiers evolve, the pyrolysis plant stands at the precipice of innovation. Integration with emerging technologies, such as artificial intelligence for process optimization or advanced catalysts for enhanced conversion, herald a promising future.

In conclusion, the pyrolysis plant, a marvel of engineering ingenuity, encapsulates the ethos of sustainable waste management. Its design intricacies and operational nuances intertwine in a choreography of efficiency and environmental consciousness, beckoning towards a future where waste is not discarded but reborn.