In general, machine and machine associated costs constitute a rather large part of any heavy duty industry business owner’s expenditures. These devices do not have much commercial viability, which means that they are somewhat more expensive to compensate for only being able to make sales to industry insiders. These machines are complicated, resource intensive, and can often be very mechanically complicated. These are all factors that contribute the the fact that these heavy duty machines often cost a great deal of money to buy and maintain. For this reason, it is generally considered heavily advantageous for companies to be able to stretch the service life of these machines for as long as possible, as this is an effective way of cutting general expenditure.

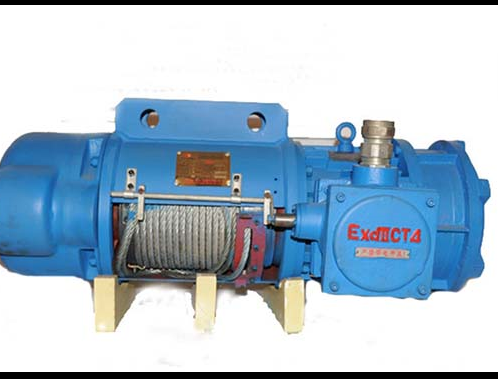

One machine that requires especially attentive care is the industrial hoist. These devices are used to life extremely heavy objects, and can sustain loads that are very large for their somewhat diminutive size. These machines require an extra amount of maintenance related caution because they are very dangerous when malfunctioning. When not cared for very well, an industrial hoists can become unbalanced and begin to sway or topple, which can put the operator and anyone around the device at risk of getting a very heavy load dropper on top of them. In extreme situations, the hoist cable can even become severed or snap. This is a particularly dangerous situation, as these devices are held at a very high level of tension, and the cable can fly out and hit people at very high speeds.

To make sure that industrial hoists are always well maintained and can be depended upon for years to come, there are two main tasks that need to be performed. The first requirement is the scheduling of a periodic mechanical check up. For this task, it is best to find a professional who has experience working with industrial hoists. If you can find an individual who knows a lot about your particular brand of hoist, even better. These experts will look at the machine and immediately notice any areas that may be broken or at risk of becoming broken. By finding and fixing problems early, you can prevent your industrial hoist from becoming even more damaged by improper function, reducing the overall amount of money that has to be spent on fixing the machine as well as replacing hoists altogether.

The next requirement for making sure that an industrial hoist has a long service life is making sure that each employee who works with the machine knows exactly what they should and shouldn’t do when using the device. Improper use of a hoist can cause the mechanical portion of the machine undue stress, cutting down its overall lifespan. In order to make sure that operation of the hoist always follows safety and effectiveness guidelines, it can be a good idea to hold a sort of class or meeting in which these things are clearly elaborated. Want this hoist? Get on https://ellsenhoist.com/industrial-hoist/.