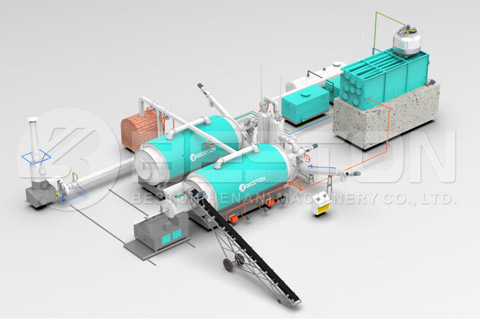

Are you interested in operating a garbage treatment plant? If you think that you might want to run a plant like this, there are numerous things you’ll have to take into consideration. You’ll need to make sure that your plant has everything that it needs to run. You’ll want to make sure you have contacts with the proper vendors. You’ll want to be aware of the municipal solid waste treatment plant costs. When recycling biomass waste, take pellet manufacturing machine into consideration.

Learn More About These Garbage Treatment Plants

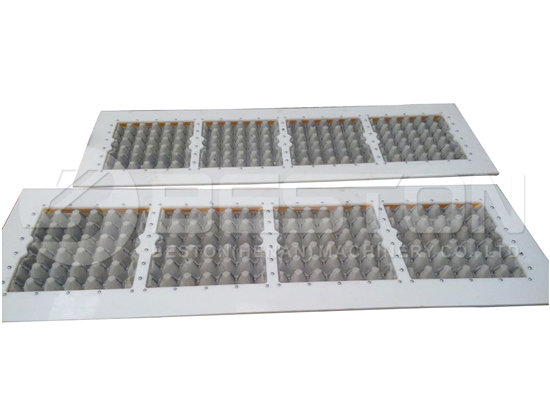

A lack of information can make it difficult for you to make decisions. You should take a closer look at garbage treatment plants and find out more about how they operate. You may want to tour the facilities that are in your area. It’s also a good idea to seek out video footage. Do you wanna know how to recycle paper waste? Get the egg tray making machine Philippines.

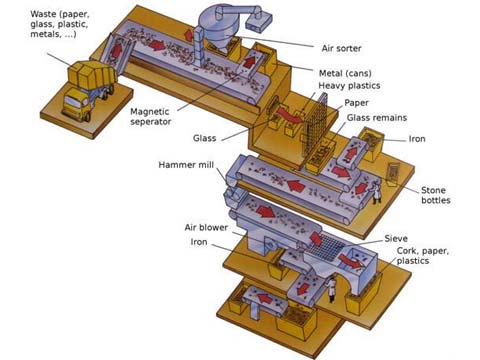

If you know more about these waste sorting machines for sale and how they are run, you’ll be able to put that knowledge to good use. You’ll have a much clearer picture of what your plant needs, and you can make a point of obtaining all of those things.

Look At The Costs Of Garbage Treatment Plant

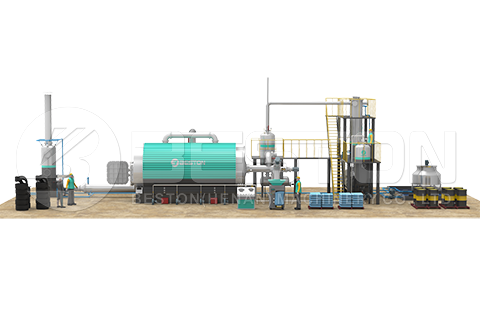

Many people that are interested in operating plants like this see the plants as an investment. If this is the position that you’re in, you’ll want to make sure that you’re fully aware of the costs associated with these kinds of plants. You’ll want to make sure you understand how much you’ll have to invest when you purchase the machinery you need, and you’ll also want to take a look at what your costs over time will look like.

Research costs before you spend any money. If you’re more careful about how you use your money, you’ll be able to make sure you use it wisely. A little bit of caution could wind up saving you a lot. If you have colleagues that you can discuss costs with, you’ll want to have a discussion with them. You’ll also want to look at some of your financing options if you’re not going to be buying your machinery with costs. You should consider your interest rates when calculating costs. If you wanna get high benefits from biomass waste, choose charcoal manufacturing equipment.

Maintain Your Machinery

One of the most common reasons people have issues with automatic waste segregation machines for sale is that they don’t take care of the machinery that they’re using. You should focus on maintaining your machinery so that it won’t break down in the future.

You can find out more about the kind of maintenance that your machinery needs if you simply look at the manual. It’s likely that you’ll find a lot of information about basic maintenance there. You should also inspect your machinery on a regular basis. If you notice any problems, you’ll want to deal with those issues swiftly. Contact the waste to energy machine supplier now.

If all of this seems overwhelming to you, you should take a deep breath and relax. Focus your attention on these things, and you should be able to run a plant while spending less. You’ll also be able to avoid a lot of the pitfalls that are associated with running these kinds of plants.