While some chicken farms raise chickens for their meat, others raise them so that they can harvest their eggs. Farms that focus on eggs should consider investing in a small egg tray machine. These machines are designed to make molded paper trays that are specifically made for holding eggs. The trays have egg-shaped indentations in the surface. An individual egg is placed in each of the indentations. Because of the way the trays are laid out, this keeps the eggs from touching one another. As a result, they are far less likely to break. Small egg tray machine can meet the needs of poultry farms and it is also affordable.

While it is possible to buy ready-made egg trays, many farms find it more economical to make their own. The trays themselves are made out of recycled scrap paper. That means that the material costs to make the trays are negligible.

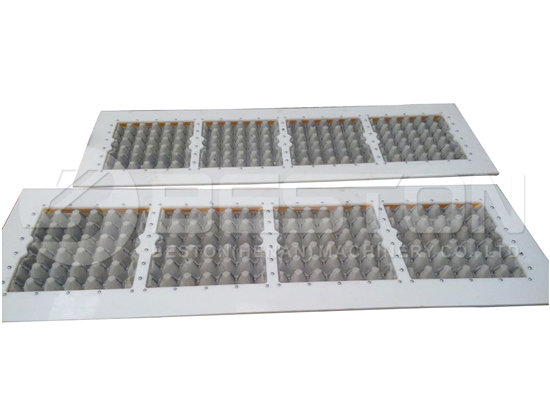

Most pulp molding machines automate the majority of the process. That means that the amount of labor involved in creating the trays is also quite minimal. For a relatively small investment of both time and money, people who run chicken farms can make their own trays, saving money over buying them from another company. Small egg tray making machine often employs a manual drying and packing system to save the investment cost. So it is also called a manual egg tray making machine. Here is a video for your reference.

Of course, it isn’t always feasible for farms to make their own trays. Some chicken farms only have a few employees or are run by families. In cases like these, there may not be enough extra time in the schedule to make the trays. Purchasing them already made could be a better option, even though it costs a little bit more.

In other situations, however, buying an egg tray machinery is a great investment. Making a batch of trays doesn’t take very long. Any extra trays that are made can be stored until they are needed. That means that chicken farmers can use any downtime that they have to create extra batches of trays so that they always have some available to use when they need them.

The process of making egg trays usually involves four basic steps. First, scrap paper is mixed with water to create a smooth, even batch of paper pulp. The pulp is strained to make sure that it is pure. From there, it is applied to special molds and shaped into the form of the trays. This is the main part of the pulp molding equipment. The trays are removed from the molds and sent through a special dryer. The dryer gets rid of any leftover water in the trays, leaving them completely dry by the time they are done.

Once the trays are created, they can be stacked together, wrapped in plastic, and stored. Farms that have a little bit of extra time to commit to making their own trays can wind up saving a lot of money. Having the machine available makes it easy to produce egg trays anytime things are slow with the rest of the farm. Any extra trays that are created can be stockpiled and stored for future use.

Chicken farms that produce a lot of eggs may benefit from buying their own egg tray making machine rather than purchasing ready-made trays for shipping their eggs. If you are looking for egg tray machine for sale, please check the website here: https://bestoneggtraymachine.com/apple-tray-making-machine/.