With a modern tyre pyrolysis plant UK, it’s possible to transform scrap tyres and waste rubber into valuable commodities. Given the fact that rubber material takes a long time to naturally decompose in landfill sites, recycling such waste material can help to protect the environment. Did you know, for instance, that a car tire takes 50 to 80 years to decompose, and during the process, lots of contaminants are released into the environment? With the right machinery, it’s possible to extract fuel oil, steel wire, combustible gas and carbon black from waste tires. They are actually a very resource dense waste material. So, if you are looking to start a profitable environmentally friendly tire recycling plant in the UK, you need to start researching the best pyrolysis reactors in the marketplace.

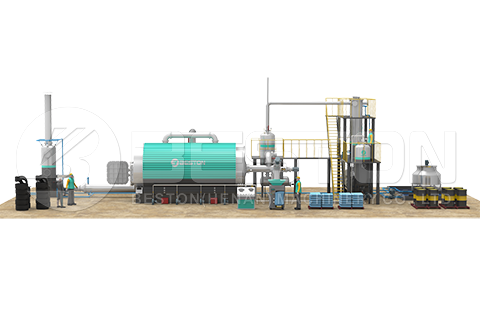

So, what is the pyrolysis process? Well, it is basically a thermal decomposition process. Materials enter an oxygen-free, sealed reactor and are heated to extremely high temperatures – typically between 250 and 300 degrees Celcius. The oxygen-free environment is essential to ensure the materials vapourize as opposed to burning. When waste tires are placed into a pyrolysis reactor, vapor containing oils of different viscosities is produced. The oils are liquified from the vapor using a complex system of water-cooled condensers. The core advantages of pyrolysis plant include no dioxin production, no combustion, environmentally friendly and energy-efficient.

One of the most popular methods of disposing of waste types is incineration. However, during that process, lots of atmospheric pollutants are produced. Pyrolysis is a great alternative to burning when it comes to dealing with rubber waste, as it results in zero environmental pollution. There are now lots of tire scrapping firms in the UK looking to invest in the best tyre pyrolysis reactors to enable them to extract higher profits from the waste and earn green cred from generous government environmental protection grant schemes.

There are pyrolysis tyre recycling plants all over the world, including in South Korea, Romania, South Africa, Indonesia, and Brazil. It is no surprise given that the safe disposal of scrap tires is a mounting global issue. The earth’s biggest scrap tire graveyard in Kuwait is so large that it can be seen from space. One of the main problems with sending tires to landfill sites is that they can trap methane gases and pose a fire risk.

In addition to burning, pyrolysis and landfill disposal, there are other ways to process waste tyres. They can be used to create artificial sports pitches, soundproof walls, and carpet underlay. They are also commonly utilized in kid’s adventure playgrounds and as flood defenses. Despite advances in tire pyrolysis plant, the majority of waste tyres are still burned for fuel. The high heat index value means that tires are a more effective heating fuel that many fossil fuels. However, as previously mentioned, the burning on tires results in a lot of air pollution, so it’s likely that as people become more aware of the environmental damage being caused, the uptake in the use of tire recycling pyrolysis machines will increase.